Code Robo

- Generate Java Code To Parse XML

- Generate Java Code To Parse JSON

- XSLT(XSL) Code Generator

- XSLT To Produce JSON(*New)

- REST API/Service Code End To End (Spring boot/MVC)(*New)

- XML To POJO(Java Bean)

- XML To JavaBean

- XML To XSD (XSD From XML)

- XML To XPath (Gen XPath)

- XSD To XML(XML From XSD)

- XSD To Java Bean(POJO)(*New)

- JSON To Java Bean

- JSON To POJO(Java Bean)

- JSON To JavaScript

- JSON To Angular Code(*New)

- JSON To AngularJS Code

- JSON Path Generator

- JSON To JSON Schema(*New)

- JSON Schema To JSON(*New)

- Generate DAO Code(SQL To Java)

- Generate JUnit TestCase(*New)

Formatter

Comparator

Tester

Merger

Converter

- Base64 To Text / Text To Base64

- Base64 To Image (*New)

- CSV To XML

- CSV To JSON

- JSON To YAML

- JSON To XML

- JSON To Text

- JSON To MappingDoc

- JSON To Excel

- JSON To Property

- Property To YAML

- Property To JSON

- SQL To JSON / XML (*New)

- XML To Excel

- Text To HTML

- XML To JSON

- XML To Mapping Doc

- XML To Template

- XML To Text

- YAML To Property

- YAML To JSON

Utility

Java Code Complience

Validator

EncoderDecoder

Virtual Service

Order Fulfillment Optimizer with Watson |

Talk to EasyAssistant |

IBM Sterling Order Fulfillment Optimizer with Watson..

Retail Challenges.

In today's world more or less every retailer in the world faced the following challenges.- Today customer expects their items 'anytime' 'anywhere' in their way

- Customers are asking for Free Shipping and that even next day! Increased customer expectations around speed of delivery

- Customer experience is the top priority

- Changes to UPS and FedEx rate calculations, that include additional charges for odd sized items .

- Bottlenecks and inefficiencies abound

- Demand for a continuous innovation

- Need to harness converging technology to build a smarter supply chain

What retailer needs?

Retailer needs an intelligent supply chain. A responsive self-correcting supply chain is the key to deliver better customer experience and high profit mergin.Order Fulfillment Optimizer with Watson

What is Order Fulfillment Optimizer with Watson?

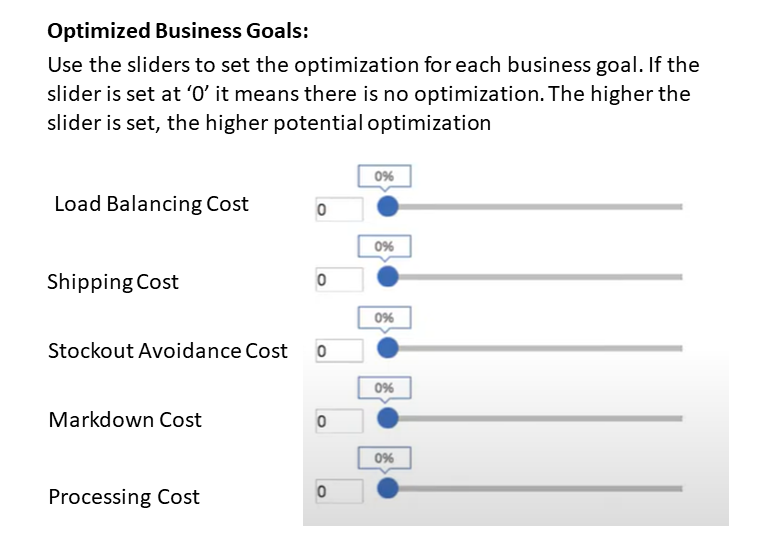

Order Fulfillment Optimizer is a AI based analytical tool which can be integrated with existing order management and inventory visibility systems to to reduce overall cost of fulfilment. Retaier will be able to act on changes in the market to maintain margins, use store capacity and meeting delivery time line, optimize inventory and fulfillment decisions to avoid stockouts, reduce markdowns, meet customer expectations, and increase profitability.

If your goal is to keep the cost of fulfillment as low as possible IBM Watson Order Optimizer can help you reduce your total cost to serve, in real-time

Other variables that Order Fulfillemt Optimizer gives weightage :

- Should the order ship from a nearby store(node) to reduce shipping costs?

- What happens if the nearest location is at low capacity and paying overtime to get products out the door

- What if the closest store only has few items left on the shelf, store may run out of inventory with the potential to lose sales of walkin customers.

Benefits of IBM Sterling’s Fulfillment Optimizer with Watson

- Optimize Inventory:

Currently (in absence of Fulfillment Optimizer) which inventory to use to fulfill a order is based on predefined sourcing and scheduling rules. That means it's rule based, pre-defined and static. It can not change the sourcing descision based on the current situation.

Where as Order fulfillment optimizer decide sourcing location to allocate the inventory at its most profitable price point minimizing markdowns and out of stocks. It continuously anlyze the data to learns sales and demand patterns and act on the next order fulfillment decision. It prioritizes slow-moving or obsolete inventory to meet eCommerce demand. Shifts inventory away from low-demand locations. Make better use of returned inventory. - Real-time Order Sourcing:

Make sourcing decisions on runtime to minimize the complete cost-to-serve which includes avoiding split of orders. Sources orders in with the knowledge on available capacity, labor, and overtime. - Improved Experience in Monitoring and Managing:

Produce insightful reports quickly and easily for business. Provides customized dashboards to show relevant to information for each individual roles. Supports natural language and allows business users to get answers in their language and take action easily. Managers can monitor operations at a high level and detail level as an when required.

Users can dynamically monitor, and gain comprehensive views across the entire enterprise. It can also detects market trends, opportunities, and patterns using cognitive abilities. Evaluates factors impacting fulfillment performance down to the individual SKU and node level. Dynamically balances between different business objectives based on time of year (peak, non-peak) and strategic considerations. - Reduce Costs:

It reduces shipping and fulfillment costs. Evaluates different carriers in real-time and acheieve least cost-to-fill. Analyzes total fulfillment costs and performance issues such as labor cost, packaging, and time to fill. Do split orders when ever is required to support least cost and do balance intelligently customer satisfaction and low cost. - Minimize Risks:

The Optimizer has the capability to create what-if scenarios and simulate them based on data and AI predictions on future demand to see how they will affect the business before making the changes live to minimize risks. This feature can also be used to test different fulfillment strategies and compare them to ensure improved efficiency and performance.

Now the important question is does every retailer need AI enabled supply chain?

It depends on how big is your fuflimment network? How many stores and DC do you have? If you only couple of store and DC in a region, then you may not need AI in your order fulfillment operation.

If you have 100s of stores and multiple DCs, Order Fulfillemt Optimizer can be benificail at great extent. Order Fulfillemt Optimizer can look at each order and compare to see which option is the best (and cheapest and fastest) to fulfill that order.

https://www.ibm.com/products/fulfillment-optimizer

https://www.ibm.com/products/fulfillment-optimizer/details

https://www.ibm.com/docs/en/fulfillmentoptimizer?topic=overview-technical

| Post Your Comment: |